A perforated screen is a type of screen that is made up of a series of small holes. These holes can be of any shape or size, but they are typically round or square. The holes are spaced evenly across the surface of the screen, and they are typically small enough that they do not significantly affect the overall appearance of the screen.

There are a number of reasons why someone might choose to use a perforated screen. One of the most common reasons is to improve the airflow through the screen. This can be beneficial in a number of different situations, such as when the screen is being used to cover an air intake or when it is being used to cover an exhaust vent.

Another reason to use a perforated screen is to reduce the amount of light that is able to pass through the screen. This can be helpful in a number of different situations, such as when the screen is being used to cover a window.

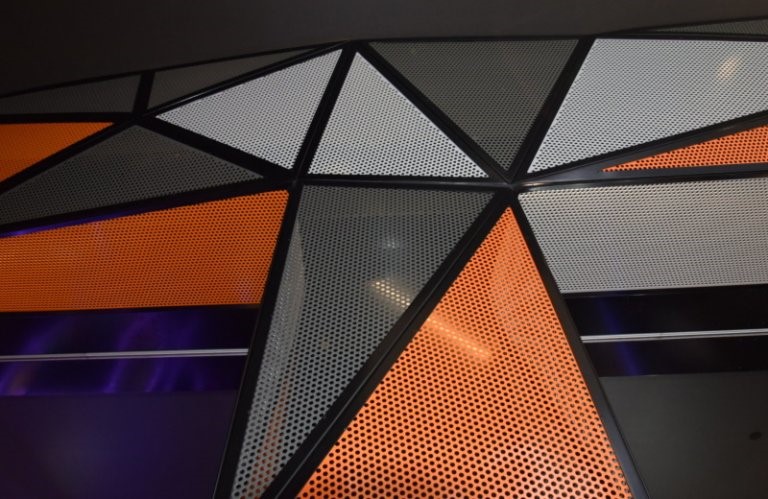

Perforated screens can also be used for decorative purposes. The small holes in the screen can create an interesting visual effect, and the screens can be used to create patterns or designs on the surface of a wall or other surface.

There are a number of different materials that can be used to make perforated screens. The most common material is metal, but screens can also be made from plastic, wood, or any other suitable material.

Perforated screens are available in a wide range of sizes and shapes. The size and shape of the holes will vary depending on the manufacturer, and the screens can be custom made to meet the specific needs of the customer.

If you are looking for a way to improve the airflow in your home or office, or if you want to reduce the amount of light that is able to pass through a window, a perforated screen may be the perfect solution.

The Different Types of Perforated Screens

A perforated screen is a type of screen that has small holes or openings in it. These holes or openings can be of different sizes and shapes, and they are usually arranged in a regular pattern. Perforated screens are used in a variety of applications, such as filtering, sieving, and straining.

The most common type of perforated screen is the metal perforated screen. Metal perforated screens are made from different types of metals, such as stainless steel, aluminum, brass, and copper. These screens can be used for both indoor and outdoor applications.

Another type of perforated screen is the plastic perforated screen. Plastic perforated screens are made from different types of plastics, such as polypropylene, polyester, and PVC. These screens are typically used for indoor applications.

Finally, there is the composite perforated screen. Composite perforated screens are made from a combination of different materials, such as metal and plastic. These screens are often used for outdoor applications.

How Perforated Screens Work

Perforated screens are a type of screen that has small holes or pores in it. These holes allow water and other liquids to pass through while still blocking out solid objects. This makes them ideal for use in filtration systems, as they can remove impurities from water while still allowing it to flow freely.

The size of the holes in a perforated screen can vary, but they are typically much smaller than the holes in a standard screen. This allows them to block out smaller particles, making them ideal for use in water filtration systems. The holes can be either round or square, and they can be arranged in a variety of patterns.

Perforated screens are made from a variety of materials, including metal, plastic, and even paper. The material that is used will depend on the intended use of the screen. For example, screens that are going to be used in water filtration systems will need to be made from a material that is resistant to corrosion.

Perforated screens can be used in a variety of applications, including:

- – Filtration: Perforated screens are often used in water filtration systems to remove impurities from the water.

- – Sifting: Perforated screens can be used to sift through powdery substances, such as flour or sugar.

- – Strainers: Perforated screens can be used to strain liquids, such as soup or gravy.

- – Ventilation: Perforated screens can be used to allow air to flow through while still blocking out solid objects.